About the author : jacksmetalwork

“Custom metal fabrication” can mean a lot of different things depending on the shop you’re working with. For some people, it means a one-off piece built for a specific need. For others, it means a repeated part run that needs to match exact dimensions every time. Either way, the quality of a custom project depends on more than welding alone—it depends on the shop’s equipment, process, and ability to handle your project from start to finish.

Jack’s Metal Works provides custom metal fabrication in the Treasure Valley and supports everything from repairs to production-style work. The easiest way to understand what a shop can do is to review its equipment and services. Jack’s lays this out clearly on their fabrication capabilities page.

Custom Fabrication Starts With a Clear Goal

A custom metal project usually begins with a specific purpose: a bracket that solves a fitment issue, a structural reinforcement, a decorative feature, or a functional component that doesn’t exist off-the-shelf. The more clearly you define what the part needs to do, the easier it is for a fabricator to recommend the right material, thickness, and build approach.

Why Shop Capabilities Matter More Than People Think

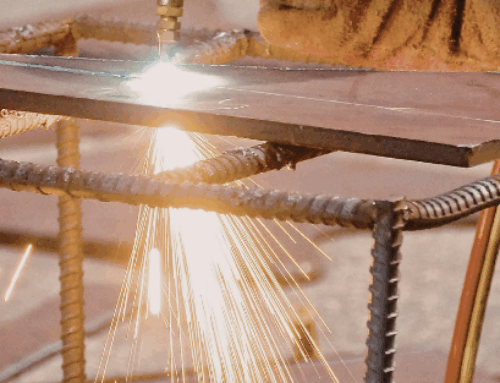

Two shops can both say they do “fabrication,” but their output can be very different based on tooling. Capabilities can include cutting, shaping, forming, rolling, bending, and welding. When these steps are handled in-house, timelines tend to be shorter and quality control is easier because fewer handoffs are required.

For example, in-house cutting like CNC plasma can improve accuracy and repeatability. And forming or braking equipment allows for clean bends that look professional and fit correctly. The end result is usually better when the shop can control the steps rather than outsourcing key operations.

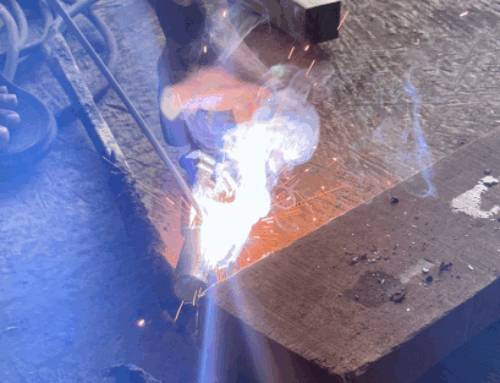

Quality and Safety: The “Unseen” Part of Great Fabrication

Good metalwork should be built to last, but it should also be built responsibly. A quality process includes attention to fit, weld integrity, and finishing details, especially for structural or safety-related components. Industry organizations like the American Welding Society provide standards and education that help guide best practices in welding and fabrication: American Welding Society (AWS).

Where Custom Projects Go Wrong

Most fabrication problems happen when a project starts without enough information. Missing dimensions, unclear mounting details, or unknown environmental exposure (like weather, chemicals, or heat) can lead to rework. That’s why bringing photos, sketches, or measurements is helpful—especially for repairs or matching an existing part.

See Real Examples Before You Commit

If you’re hiring a metal shop, one of the best steps you can take is to look at examples of past work. Jack’s Metal Works shares finished projects in their metal project gallery, which helps customers understand the range of work the shop can support.

Custom fabrication is ultimately about solving a problem with a durable, well-built result. When you choose a shop with the right equipment, a clear process, and a strong track record, the entire experience becomes smoother—communication improves, timelines shorten, and the finished product fits like it should.