Metal Fabrication Techniques That Can Increase Your Bottom Line

jacksmetalwork2023-05-15T01:52:26+00:00As a custom metal fabricator, there are ways to differentiate yourself from standard metal fabricators and offer more value to your customers. Providing a full range of services can be a significant advantage since customers are always looking for value. By bringing value to the situation, you can stand out from the competition in several ways.

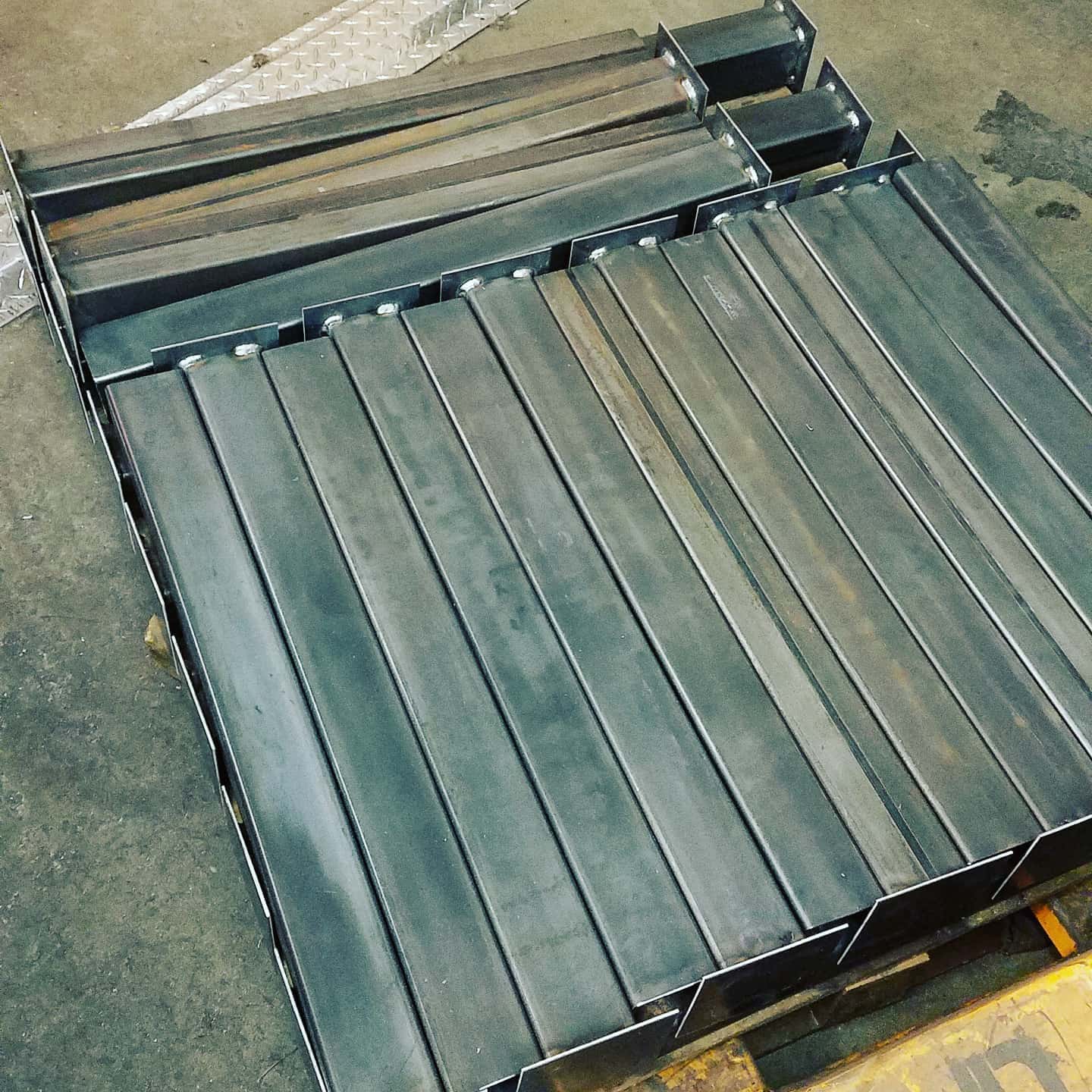

To begin with, metal fabrication requires careful research and assessment of the materials and methods required to create a design in the most cost-effective way possible. Since custom metal fabrication is a highly detailed process, producing durable and high-quality results can bring great value to your customers. Whether you’re creating a small accessory or a large building, your customers will appreciate the value you bring to the table.

Furthermore, earning your clients’ trust and increasing your bottom line can be accomplished by providing long-term value. As a custom metal fabricator, you can achieve this by delivering superior quality workmanship that lasts for years. By doing so, you will differentiate yourself from your competitors and establish yourself as a trusted and valued partner to your clients.

To add value to your services as a fabricator, it’s crucial to begin by considering the purpose or value of the fabrication project. Regardless of the project, the customer has a need that you are helping to fulfill. Offering unique solutions to their problems is a way to differentiate yourself from your competitors.

As a full-service fabricator, you may want to consider taking standard plans or engineering drawings and finding ways to improve them, creating a more desirable product. By refining and testing the design to meet specific industry needs, you can add significant value to your services. This approach can help ensure that the final product is not only functional but also efficient and long-lasting. In doing so, you are setting yourself apart from others in the industry and demonstrating your commitment to providing high-quality results for your clients.

Customizing fabrication projects to meet industry-specific needs is a valuable process for all fabricators. When working on projects like silos, hoppers, or tanks, it’s important to consider the materials that will be stored to ensure proper customization. For liquid food storage, there are customization options like adding filters or other accessories to help maintain the quality of the stored material. Additionally, adding features like a special staircase or crossover platform can be a significant benefit to the storage unit and its users.

By offering these types of customized solutions, fabricators demonstrate thoughtfulness and add value for their customers. For experienced fabricators who are skilled in computer-generated design, the customization process can be quick and efficient. This allows the fabricator to present ideas to their customers before any actual fabrication takes place. Ultimately, by providing customized solutions that meet industry-specific needs, fabricators can differentiate themselves from their competitors and provide greater value to their customers.

Metal cutting and forming are additional areas where value can be added to metal fabrication projects. Metal fabricators must select materials prior to cutting or forming, and these choices can impact both the cost and function of the project. Presenting customers with options for material selection that may add value to their project is an excellent way to earn more business. Sometimes, a project may call for a certain material, but fabricators are aware of the drawbacks or benefits of different materials that may impact this choice.

The methods of cutting the metal are also important to consider when determining the type of project and the required material. For instance, structural steel projects often require sawing over laser cuts due to limitations in laser cutting. Recognizing these limitations can impact design and prevent problems before a project begins, ultimately saving the client money. Similarly, using a plasma machine can provide top-level precision, but not all mediums work well with plasma tables. Therefore, if a project requires this level of precision, ensuring the right material is chosen is critical.

Metal fabricators can provide value to the customer by advising them about these limitations or benefits before a project begins. By sharing their expertise, fabricators can guide their customers towards the most appropriate material and cutting methods, resulting in a better quality end product. This level of guidance and expertise can set a metal fabricator apart from their competitors, ultimately leading to greater customer satisfaction and repeat business.

Forming metal often requires techniques such as bending, plating,rolling, or punching. Using the right machinery for each of these processes is crucial to achieving the desired results.

Custom welding and assembling techniques are how metal fabricators meet industry standards. Fabricators should have certified welders and a documented quality control program to demonstrate the value of their work. Displaying the quality of their work can add value to their sales pitch and attract potential customers or clients. When working with a welder, clients should look for specific certifications depending on the size and type of structure being created. Having a portfolio and a list of certifications is an excellent way for a welder to set themselves apart from the competition.

The final finishing of a project is a critical aspect that showcases a metal fabricator’s abilities. It is often the aspect that they are judged on. The final finishing of a project has a significant impact on its durability and resistance to corrosion. Outdoor projects, in particular, require great finishing techniques to ensure that they do not corrode over time due to exposure to the elements.

Metal bead blasting and other surface preparation techniques are great methods for finishing a project. Painting and drying are also essential areas that require attention to detail, as proper drying and handling are critical to the painting process. Hot dip galvanizing and metal powder coating are also essential techniques that a metal fabricator should have in their repertoire, especially for many applications.

By offering these finishing techniques and demonstrating expertise in their execution, metal fabricators can set themselves apart from their competitors and add value to their services.

Metal fabricators are skilled professionals who create both functional and aesthetically pleasing structures. Adding value to their work through innovation, creativity, and attention to detail is essential to stand out from the competition. However, sometimes the value in their work can be overlooked if not communicated properly to potential clients. This is where a sales team can come in handy to effectively convey the benefits and value of their work. Overall, the metal fabrication industry offers a range of opportunities for customization and creativity, and adding value to projects through various means can lead to increased success and recognition for metal fabricators.