Small Business + Contractors: Why Consistent Fabrication Quality Matters

jacksmetalwork2026-01-09T14:50:45+00:00For small businesses and contractors, metal fabrication isn’t just about making parts — it’s about reliability, repeatability, and consistency. When fabricators understand quality expectations and deliver parts that meet specifications every time, the entire job goes smoother. Whether you’re installing railings, brackets, stairs, gates, or structural elements, consistent quality leads to fewer callbacks, faster installs, and better project outcomes.

Jack’s Metal Works works with local contractors and small businesses on a wide range of projects, from one-off parts to repeat orders. When quality is high and consistent, contractors can confidently plan around turnaround times and fitments.

What “Consistency” Looks Like in Fabrication

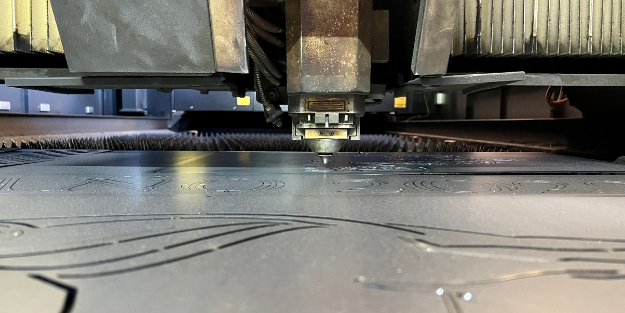

Consistency means that material thickness, dimensions, tolerances, and finishes are uniform from one part to the next. This is especially important in repeat orders or when parts interact with preexisting structures. CNC cutting, precise bending, consistent weld quality, and clean finishes all contribute to consistent results.

For example, automated CNC plasma cutting helps ensure each part matches specifications with minimal variance, which is key when a contractor needs a batch of identical plates or brackets. Knowing that the parts will fit as drawn reduces on-site adjustments and saves labor time.

Communication Reduces Errors

Another key to quality consistency is clear communication. When contractors share detailed drawings, tolerances, and material specs up front, fabricators can plan the right tools, sequences, and quality-control steps. Projects start with clarity rather than guesswork.

Contractors and small businesses that invest a little time in clear documentation often see the biggest returns in installation speed and fewer revisions.

Why Quality Impacts Your Bottom Line

Rework or out-of-tolerance parts cost time and money. Installation delays, on-site modifications, and last-minute adjustments can interrupt schedules and increase labor costs. When fabrication quality is reliable, these risks are dramatically reduced. Reliable quality contributes to smoother project flow and satisfied clients.

The National Institute of Standards and Technology (NIST) explains why consistent manufacturing quality helps reduce variability and improve outcomes: NIST manufacturing quality.

How Shops Support Contractors and Businesses

A good fabrication partner understands contractor needs. That means:

- Delivering accurate quotes

- Meeting deadlines consistently

- Providing clear updates and timelines

- Maintaining tolerance control across parts

Jack’s Metal Works offers these capabilities, giving contractors confidence in material quality and precision. Their fabrication capabilities page outlines the tools and services they use to support repeat quality.

Choosing the Right Fabrication Partner

Contractors and small business owners benefit when the fabricator becomes a trusted partner rather than just a vendor. When you can rely on consistent quality, your own service delivery improves. That’s good for your clients and good for your reputation.

Quality metal fabrication isn’t just a technical detail — it’s a foundation for dependable project execution and long-term success.